Mobile:023-67162778

Phone:18184765876

Fax:023-67162779

Email:kaperior@qq.com

Address:No. 88, Qinye Road, Konggang Industrial Park, Yubei District, Chongqing

Product Usage:

Widely used in corrosive fluid pipeline systems or manufacturing equipment such as agricultural machinery, medical equipment, biopharmaceuticals, chemical engineering, sewage treatment equipment, canning equipment, etc. Suitable for supporting products of chemical fluid automation production equipment using various corrosive chemical fluids as media.

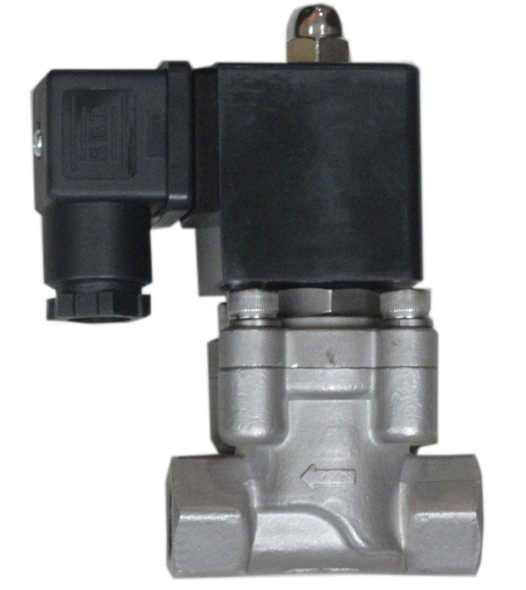

Structural features:

Products specifically designed for chemical fluid media;

All components that come into contact with fluids are made of corrosion-resistant and acid alkali resistant plastics and seals;

The reset spring is set outside the fluid, which is not easy to block, resistant to acid and alkali corrosion, and has a long service life;

Piston structure and stable performance;

Autocratic coil, not easy to burn;

Product parameters:

★ Product specifications: DN1~DN100

★ Applicable media: ammonia, ammonia liquid, and acidic or alkaline liquids or gases mixed with organic solutions

★ Control mode: normally closed, normally open, self holding type

★ Valve body material: PTFE, PVC, ABS, stainless steel 316

★ Power supply voltage: DC12~127V AC36~380V

★ Medium temperature: -50~(+100+200 ℃)

★ Pressure range: 0~1.6Mpa

★ Medium viscosity: less than 50Ct (customized if greater)

★ Connection methods: flange, welding, internal thread (external thread and special interfaces can be customized or equipped with adapters)

★ Protective performance: dustproof, waterproof, explosion-proof. Select based on operating conditions

★ Wiring method: socket type; Lead type; Plug in type

★ Leakage rate: zero

working principle:

Normally closed type: When the coil is energized, the pilot valve core is attracted, the pilot hole is opened, the upper chamber of the valve is depressurized, the piston is pushed by the pressure of the lower chamber medium, and the solenoid valve is opened; When the coil is powered off, the pilot valve core is reset by the spring, the pilot hole is closed, the upper chamber of the valve is pressurized by the piston throttle hole and the thrust of the reset spring, and the solenoid valve is closed.

Normally open type: When the coil is energized, the pilot hole closes, and the upper chamber of the valve is pressurized by the piston orifice and the thrust of the reset spring, causing the solenoid valve to close; When the coil is powered off, the pilot valve core is reset by the spring, the pilot hole opens, the upper chamber of the valve is depressurized, the piston is pushed by the pressure of the lower chamber medium, and the solenoid valve opens.

Note:

The external dimensions are generally applicable to medium and low pressure solenoid valves and anti-corrosion solenoid valves.